Embarking on a home renovation or extension project is an exciting prospect. Whilst plans for new kitchens and loft conversions often take centre stage, the foundational work required to make these dreams a reality can be less glamorous but is critically important. One such process is concrete cutting, a specialist trade that is fundamental to many residential projects, from creating a new doorway to installing modern utilities.

Understanding the methods and processes involved can empower homeowners to have more informed conversations with their builders and contractors. This guide provides a detailed overview of concrete cutting in a residential setting, exploring the techniques, the process, and the crucial safety considerations involved.

Why is Concrete Cutting Needed in Home Projects?

At first glance, the idea of deliberately cutting into the structural fabric of your home might seem counterintuitive. However, it is a necessary procedure for a wide range of common renovations. Concrete, whilst strong and durable, often needs to be altered to accommodate new designs or functional requirements.

For instance, you may require concrete cutting to create openings for new windows in a basement conversion, or a doorway to connect your home to a new extension. It is also essential for removing sections of a concrete floor slab to lay new drainage or utility pipes. Other common applications include creating channels, known as chases, in walls or floors for electrical wiring and plumbing, or removing a section of a concrete patio or driveway to redesign an outdoor space. In essence, any project that involves modifying existing concrete or reinforced concrete structures will likely require a form of precision cutting.

The Primary Methods of Residential Concrete Cutting

The term ‘concrete cutting’ encompasses several distinct techniques, each suited to different applications. The choice of method depends on the thickness of the concrete, the location of the cut, and the desired outcome. The technology relies on industrial diamond-tipped blades and drills, as diamond is one of the few materials hard enough to cut through aggregate, cement, and steel reinforcement bars (rebar) with precision.

Diamond Wall Sawing

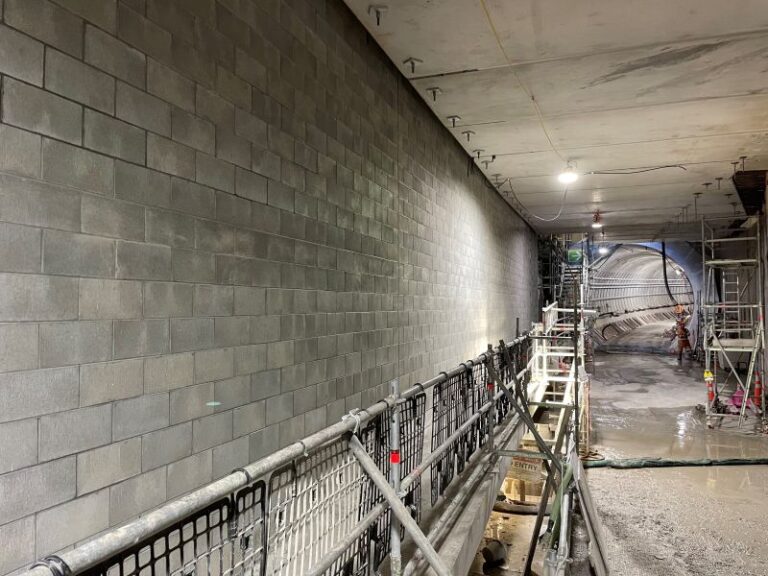

When a project requires creating precise, clean openings in vertical concrete surfaces, wall sawing is the go-to method. This technique is ideal for fashioning new doorways, window apertures, and ventilation openings. The saw itself is a powerful circular blade mounted on a track system that is bolted directly to the concrete wall. This track guides the saw, ensuring perfectly straight and plumb cuts, which is vital for the subsequent installation of frames and fixtures. The process is remotely operated, which enhances safety for the tradesperson. Wall saws can cut to significant depths and are effective on heavily reinforced concrete.

Floor Sawing (or Slab Sawing)

For horizontal surfaces like concrete floors, driveways, and suspended slabs, floor sawing is the appropriate technique. These powerful, walk-behind machines are guided by an operator and can cut through thick concrete and asphalt with accuracy. Floor sawing is commonly used to cut trenches for plumbing and electrical services, to remove a damaged section of a concrete slab for repair, or to create expansion joints that help prevent random cracking. For larger areas, ride-on saws may be used. The precision of floor sawing ensures that the surrounding concrete remains structurally sound.

Core Drilling

Unlike sawing, which creates linear cuts, core drilling is used to create perfectly circular holes in concrete. A hollow, cylindrical drill bit tipped with diamonds rotates to grind away the concrete, leaving a hole and a solid core of material that is then removed.

This method is exceptionally useful in residential settings. Plumbers require core drilling to run pipes through walls and floors. Electricians use it to create pathways for conduits and cabling. It is also necessary for installing ventilation systems, HVAC pipework, or even creating holes for anchoring bolts in foundations. Core drills come in a wide range of diameters, from small holes for a single cable to large openings for drainage mains.

The Concrete Cutting Process: A Step-by-Step Overview

A professional Auckland concrete cutting job is more than just turning on a saw. It involves a meticulous, multi-stage process to ensure safety, accuracy, and structural integrity.

-

Step 1: Site Assessment and Planning

A specialist will first assess the site. This includes identifying the type and thickness of the concrete and using scanners to locate hidden utilities, pipes, and rebar within the slab or wall. For any load-bearing structures, a structural engineer may need to be consulted to approve the plans and specify any temporary supports required. -

Step 2: Marking Out and Preparation

The area to be cut is measured and marked with absolute precision. The surrounding area is prepared to manage water and debris. This may involve laying down protective sheeting and setting up barriers to ensure the work zone is secure. -

Step 3: The Cutting Operation

The chosen equipment—be it a wall saw, floor saw, or core drill—is set up. A crucial part of modern concrete cutting is water management. A steady stream of water is directed onto the blade or drill bit. This serves two vital purposes: it cools the diamond tip to prevent overheating and it suppresses the creation of airborne dust. -

Step 4: Controlled Removal and Disposal

Once the section is fully cut, it is carefully removed. For larger pieces, lifting equipment may be used. The goal is a controlled removal that does not damage any adjacent structures. The contractor will then manage the disposal of the concrete, often taking it to a recycling facility where it can be crushed and reused as aggregate.

Safety & Structural Integrity: The Non-Negotiables

Attempting to cut concrete without proper training and equipment is hazardous. The most significant risk is exposure to respirable crystalline silica (RCS) dust. When concrete is cut dry, it creates a fine dust that, if inhaled, can cause serious and irreversible lung diseases like silicosis. Wet cutting, where water is used to dampen the dust at its source, is the industry standard for mitigating this risk. Professional operators also wear appropriate personal protective equipment (PPE), including masks, eye protection, and hearing protection.

Furthermore, indiscriminately cutting into concrete can compromise the structural integrity of a building. Cutting through a load-bearing wall or a key structural beam without proper engineering guidance and temporary propping could have severe consequences. A qualified concrete cutting firm understands these risks and will work in line with structural engineering plans to ensure the building remains safe throughout the process.

Summary

Concrete cutting is a highly skilled trade that plays a pivotal role in bringing residential renovation plans to life. From the precision of wall sawing for a new window to the functional accuracy of core drilling for new plumbing, these methods allow for significant and beneficial alterations to a home’s structure. By understanding the different techniques and the rigorous process involved, homeowners can better appreciate the expertise required. Given the emphasis on structural integrity and health and safety, engaging a professional and reputable concrete cutting service is not just a recommendation; it is an essential step towards a successful and secure home renovation project.

For an expert concrete appraisal in Auckland call Russell Gordon on 0800742100 or email enquiries@rgc.co.nz